SEQUESTRATION MANAGEMENT

Our unique carbon capture and storage technology captures and permanently buries carbon dioxide in unmineable coal seams through a safe and efficient process. In partnership with our sister company, WellDog, our downhole systems have been used in thousands of locations around the world to directly measure and monitor key geophysical and geochemical data in the subsurface. Our technology can capture and store carbon dioxide from a variety of emission sources, including power plants, hard-to-decarbonize industries like cement and paper, and ultimately, from the atmosphere via emerging direct air capture (DAC) technologies and stores it underground.

Manage Conventional CCS

Carbon GeoCapture has unique experience operating high-profile conventional carbon sequestration projects. Our company is one of very few in the United States to navigate the complex Environmental Protection Agency’s (EPA) Class VI well permitting process, developed specifically for carbon sequestration in geologic formations. Since this permit category was created in 2010, there are only two active Class VI wells operating in the United States. The Class VI permit is designed primarily to protect underground sources of drinking water, making it a particularly stringent permit to obtain.

Carbon SAFE Project

CarbonSAFE (Carbon Storage Assurance Facility Enterprise) is an initiative that began in 2016 by the U.S. Department of Energy (DOE) with the goal of addressing the key gaps standing in the way of greater carbon capture and storage (CCS) deployment. The initiative aims to develop and refine technologies and techniques so that each carbon dioxide storage complex can safely, permanently, and efficiently sequester over 50 million metric tons of CO2.

Wyoming CarbonSAFE is being led by the University of Wyoming’s Center for Economic Geology Research (CEGR), and is one of 13 original carbon capture, utilization, and storage (CCUS) project sites in the United States funded by the DOE with the goal of ensuring carbon storage complexes will be ready for integrated CCUS system deployment. Wyoming CarbonSAFE is focused on investigating the feasibility of practical, secure, and permanent geologic storage of CO2 emissions from coal-based electricity generation facilities near Gillette, Wyoming.

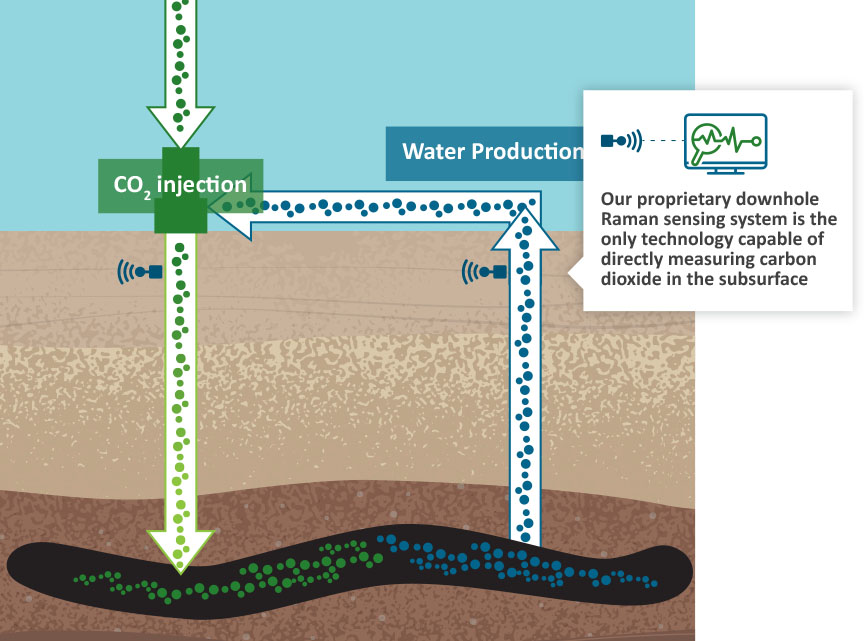

CGC was brought on by the CEGR as an industrial partner to manage the field operations for this project. We were selected based on our management expertise and our proprietary downhole Raman sensing system. Our combined experience and subsurface monitoring capabilities has been able to confirm that carbon dioxide can be safely and permanently buried in the ground without contaminating underground drinking water.

Manage Unconventional CCS

Our unique carbon capture and storage technology permanently buries carbon dioxide in unmineable coal seams through a safe and efficient process. Coal beds occur widely, underlying most of the world’s land mass. These carbon sinks occur at shallower depths than conventional reservoirs (including sandstone and carbonate).

Monitor and Verify CCS

In partnership with WellDog, our sister company from which CGC was created in 2016, our patented downhole Raman spectrometers systems have been used in thousands of locations around the world to directly measure and monitor key geophysical and geochemical data in the subsurface. These subsurface monitoring systems include:

WatchDog: an electronic or fiber optic downhole monitoring system engineered to overcome two historical client challenges: cost and reliability. Systems are cost effectively engineered and used to characterize and optimize production, or to conduct long term surveillance of reservoir performance.

PermSpotter: technology which provides a means for determining bulk permeability from monitoring and analysis of pressure transients induced in the reservoir.

GasSpotter: a coal-focused technical service that uses the industry’s only downhole wireline and wellhead Raman spectrometer systems to measure key reservoir parameters of gas composition, gas content, critical desorption pressure, gas saturation, and required drawdown to production.

SweetSpotter: a coal reservoir-focused technical service that combines both the GasSpotter and PermSpotter technical services to deliver gas composition, gas content, critical desorption pressure, gas saturation, required drawdown to production and permeability data.

Reservoir RockHound™: a mineralogical and geochemical characterization service for shale reservoirs. This service uses industry-leading laboratory-based Raman spectroscopy to expediently, cost effectively and accurately characterize both mineralogical and geochemical makeup of reservoir samples.

These sensors take an agnostic approach to technology selection and deliver engineered fit-for-purpose subsurface monitoring solutions. These solutions take into consideration pressure sensor types, covering a variety of pressure ranges, that are available with different temperature ratings, and capable of either analogue or digital transmission of data.

WellDog has also pioneered a number of different gauge architectures and deployment methods that allow one or more gauges of the same or different type, to be installed in the same well, either on tubing, coil, and/or behind casing. This high degree of flexibility enables permanent downhole monitoring systems to be configured to exactly suit well and reservoir conditions, and data needs.