Powering AI Responsibly: The Case for Coal-Assisted CCS

Earlier this year, Future in Review (FiRe) honored CGC as a FiReStarter at their annual event in San Diego. FiReStarters are invited to write a guest letter about the industry in which they operate, the promise it holds, and the ways in which our future might be improved by taking action in that space. This article by CGC’s President and CEO, John Pope, outlines the compelling value proposition that coal-assisted CCS can provide for power and data center developers and the tenants and cloud companies that rely on them.

But burning hydrocarbons to generate power is also the primary driver of climate change. As we build out the next generation of AI infrastructure, we are increasing carbon emissions from power plants just when we need deep reductions. That is the core tension: how do we support the growth of AI and data centers without abandoning our climate goals?

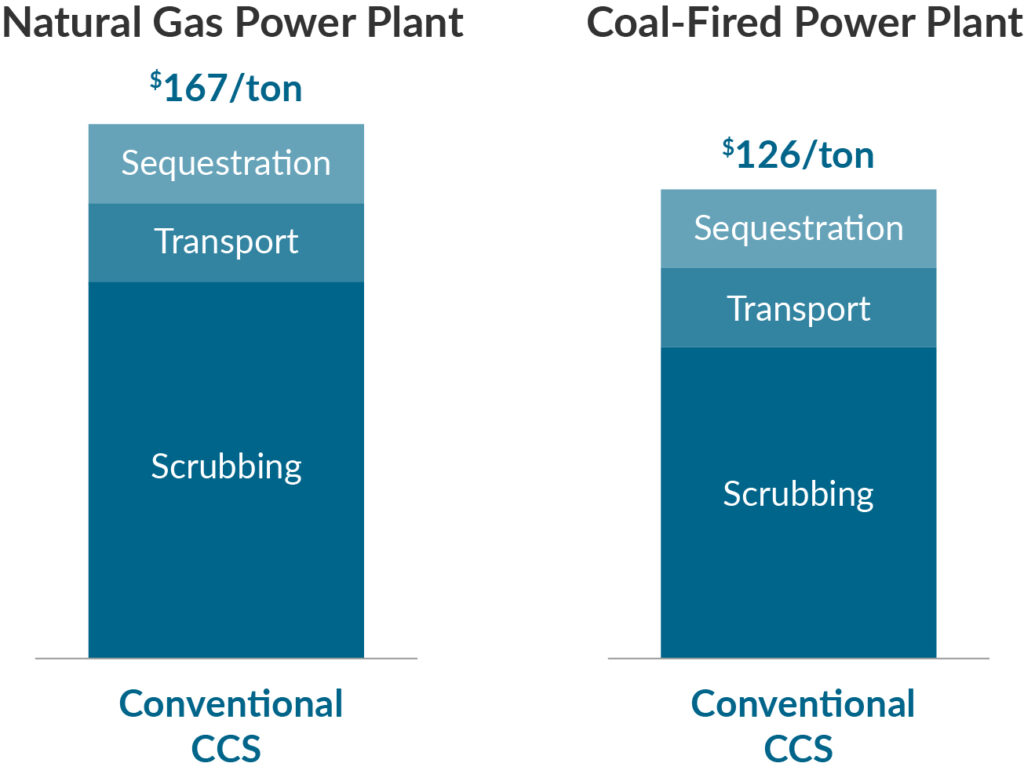

Why Conventional CCS Falls Short

Many people look to carbon capture and storage (CCS) as the way to keep using firm power from hydrocarbons while reducing the impact from their carbon emissions. In principle, CCS should allow us to burn hydrocarbons for firm power while preventing most of the resulting CO2 from reaching the atmosphere. In practice, conventional CCS has proven too expensive for most real projects, especially on natural gas power plants.

Combustion of hydrocarbons emits dilute streams of CO2. Conventional CCS methods assume that we will scrub those flue gases to produce an almost pure CO2 stream, then compress, transport, and inject it into deep rocks at high pressure. Scrubbing and purification is where the economics break down. Doing so is capital- and energy-intensive and becomes particularly costly when the flue gas is more dilute, as it is for natural gas-fired power.

If you stack up the costs of a typical conventional CCS project on a power plant – capture equipment, scrubbing, compression, pipelines, injection wells, long-term monitoring – the total is higher than what existing policy support and power markets can sustain.

Figure 1 shows an illustrative cost stack for conventional CCS on coal- and natural gas-fired power. It highlights that that scrubbing accounts for the largest share of total cost. CCS of natural gas-fired power costs the most because its flue gas is the most dilute of all, about 4% CO2. Coal-fired power flue gas is about 12% CO2, making it more affordable to scrub.

Figure 1 (Graphics Courtesy Carbon GeoCapture)

In the United States, the Section 45Q tax credit provides $85 per ton of CO2 captured and stored. In practice, it is insufficient to pay for CCS on coal-fired or natural gas-fired power plants when conventional methods are used. It’s also insufficient to pay for CCS for most other types of plants that emit CO2, including cement, steel, fertilizer, trona, and chemical facilities. In fact, the 45Q tax credit is insufficient to support CCS for the carbon emitted by more than 80% of our stationary CO2 point sources. Unsurprisingly, in 2025 we’ve seen most conventional CCS projects in the US either paused, canceled, or quietly slowed down. The economics simply do not work.

As a society, we are not reducing our existing carbon emissions, and we’re about to dramatically increase them to support the energy needed to power AI. We face a reality in which AI and data centers are driving demand for firm power, firm power is likely to come from hydrocarbon-fired power, and conventional CCS is too expensive to make that power low-carbon intensity.

Two Choices to Address Carbon Emissions

If we want to responsibly produce power for AI, our choices are limited: increase what we’re willing to pay to manage the related carbon emissions or find ways to manage those emissions more cheaply and effectively. These choices aren’t binary or mutually exclusive; it’s reasonable to pursue both in parallel.

The AI industry might help us with the first option by paying a premium for hydrocarbon power equipped with CCS. Paying a premium of at least $0.10 per kWh might be sufficient, although that number is highly dependent on project location, situation, and rapidly appreciating supply-chain costs. Whether the AI industry can afford that premium remains uncertain. To date, it has mostly not chosen to pay for it.

In parallel, we can work to get better at storing the resulting CO2 at a cost that society will accept, and markets will bear, now. This is where coal-assisted CCS comes in.

Coal-Assisted CCS

At Carbon GeoCapture (CGC), our focus has been on that second option: managing emissions more cheaply and effectively. Our approach continues a technical path pioneered by others over the past 120 years. That path involves putting CO2 into coal seams deep in the ground that will never be mined.

Coal is a polarizing topic when it’s used as fuel. But unmineable coal seams can also serve as an effective and secure sink for CO2. In its natural state, coal is a complex nanoporous sponge that contains water and methane (natural gas). Its propensity to act as a carbon filter for gases is well documented. In fact, coal prefers to sorb CO2 more than other naturally occurring gases, including nitrogen and methane. Over the last few decades, companies have sequestered hundreds of thousands of tons of CO2 in coal to produce the methane those seams contain.

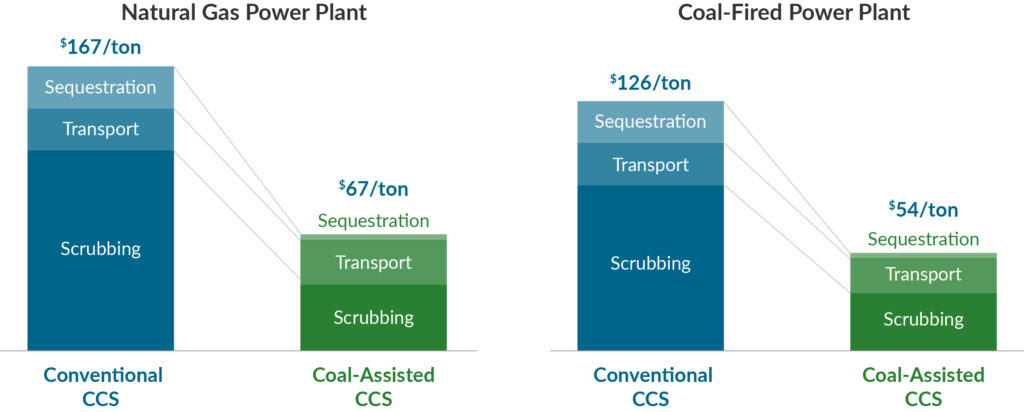

Coal is not just a storage medium; it is also a filter. As flue gas moves through the coal, CO2 is captured and adsorbed, while the balance of the gas – mostly nitrogen – moves on. If we design our system around these natural properties, we can change the assumption that we must first create a nearly pure CO2 stream before injection and instead inject dilute flue gas directly into coal seams, allowing the coal itself to separate and store the CO2.

This has important economic consequences: we avoid the largest and most expensive component of conventional CCS projects – large, energy-hungry scrubbing units; we simplify the surface plant; and we shorten and de-risk the infrastructure we need to build.

By letting coal act as both a filter and a sink, coal-assisted CCS can reduce the cost of managing each ton of CO2 to the point at which existing incentives like 45Q in the US are sufficient to make many projects viable, including projects linked to hydrocarbon-fired power.

Figure 2 shows the same cost stack comparison with coal-assisted CCS in place of conventional CCS and illustrates how eliminating scrubbing dramatically reduces total system cost.

Figure 2

In addition to the cost benefits of coal-assisted CCS, the approach provides some other key benefits:

- The option to produce natural gas, which can be used as a fuel in power plants, while at the same time storing far more CO2 in the ground than the amount of carbon contained in the natural gas produced. Coal can store 10 to 20 times more carbon than is produced as natural gas. Coal-assisted CCS can be heavily carbon-negative.

- If we do produce natural gas, the ability to use Class II underground injection permits in the US, which are cheaper and faster to obtain than Class VI permits.

- A closed-loop water flow system from and to the coal seam that protects shallow drinking-water aquifers.

- The opportunity to use coal-seam water in cooling systems for data centers, further protecting surface and shallow-aquifer waters.

What CGC Has Learned

At Carbon GeoCapture, we have been working on coal-assisted CCS for over 20 years, standing on the shoulders of many who came before us – learning from their work, refining their methods, and testing those ideas in the field. We have drilled and operated test beds, including at the Neil Simpson coal-fired power plant complex in northeast Wyoming, injected CO2 into coal seams, and monitored the results.

Over that time, we have achieved three key milestones that make coal-assisted CCS a practical tool for large-scale carbon management:

- Conclusive monitoring, reporting, and verification. Starting in 1999, we developed and commercialized a unique downhole sensor that allows us to directly measure CO2 (and nitrogen and methane) deep in the ground, so we can confirm where it goes and that it stays there.

- Underpressurized sink. We refined the coal-assisted CCS method to avoid the overpressurized sink challenges inherent to conventional CCS. Instead, we work with the natural coal seam water pressure to hold the CO2 in place for the long term.

- Sequestration of raw flue gas. We have shown that coal seams can capture CO2 out of dilute flue gas streams with little or no scrubbing, improving the economics possible with CCS.

Together, these advances are what make coal-assisted CCS capable of supporting large-scale deployment now. We’re using known reservoir physics, established engineering and drilling techniques, and naturally occurring coal formations that lie beneath many of the places where we already generate power.

Powering AI Data Centers

Once we recognize that AI data centers will rely on hydrocarbon-fired firm power for at least the next decade, and that coal-assisted CCS can manage the resulting CO2 at a cost and scale conventional CCS cannot, the question becomes: where should we build the next generation of AI infrastructure?

There are regions of North America where several key parts line up:

- Unmineable coal seams suitable for coal-assisted CCS

- Hydrocarbons that can be used as fuel

- Existing or expandable fiber-optic infrastructure

In these regions, it would be possible to produce hydrocarbons, burn them for power, power a data center, cool the data center, capture the related carbon emissions, and store those emissions in the underlying coal seams. This concept could be executed off-grid and behind the meter – and without new natural gas pipelines or power transmission infrastructure.

As one example, the map in Figure 3 shows major coal deposits in the US overlaid with the location of existing fiber-optic cables. It highlights broad regions where hydrocarbon fuel, subsurface storage potential, and digital connectivity already coexist and where new AI power campuses could be sited to take advantage of that overlap.

Figure 3

And since coal-assisted CCS can be added to hydrocarbon power plants, those campuses can start operating now, while we plan and build the CCS systems and future-proof the campuses from policy swings.

Scale, Limits, and CGC’s Role

Coal-assisted CCS is not a universal solution. Like other geosequestration approaches, it is constrained by available geology. Only a portion of the world’s stationary point sources sit over coal basins with the right characteristics. Not every power plant or industrial facility can be paired with a local coal sink.

At the same time, stationary point sources worldwide emit around 15 billion tons of CO2 per year. Our analysis suggests that about 40% of the plants emitting that carbon are located on top of, or near, viable coal sinks.

Abating the carbon emissions from those plants would require on the order of 8,000 projects.

How to Help

Coal-assisted CCS will not, by itself, solve climate change or decarbonize the entire power sector. But it does offer a way to provide low-carbon firm power from hydrocarbons at a cost that aligns with existing incentives and markets. It is one of the few tools we have today that can support the growth of AI and data centers while meaningfully reducing the emissions associated with their power in a responsible manner.

Carbon GeoCapture is currently managing a pipeline of just 25 projects in North America (representing about 35 million tons of annual CO2 sequestration capacity). The company has a long way to go, and scaling up quickly is its focus. Here are three ways to get involved:

Invest in the company.

Despite the size of the challenge Carbon GeoCapture is tackling, it remains a small, angel investor-supported company. If you are an accredited investor who sees the value in funding an actual business to expand this work, the team invites you to join them.

Help CGC do more projects, faster.

Like most project developers, we are capital constrained. Early-stage funding for our projects can be difficult to find, even when they are credibly estimated to be highly profitable. Our industrial and power-plant partners sometimes do not have the ability to move quickly – or at all. We’re eager to work with financial partners and other project developers to accelerate the process.

Work with the company to abate your emissions.

CGS can quickly scope whether your carbon emission source is close enough to a coal deposit to support a profitable, attractive project. Contact John Pope at jpope@carbongeocapture.com to discuss working together to reduce emissions from industrial and power plants and responsibly support the expansion of AI.

Watch the video of John’s FiRe 2025 pitch.

Originally published by Strategic News Service in the SNS Global Report™ (Vol. 30, Iss. 40, Nov. 2025). Copyright © 2025 Strategic News Service and John Pope for Carbon GeoCapture. Redistribution prohibited without written permission.